After setting the posts in the ground, it is time to assemble the gate, according to the plan.

The best way to notch galvanized pipe is to use professional pipe notcher, however those tools are not cheap, especially for pipes bigger than 2″ in diameter. It doesn’t seem to be a good investment if I only need to use it for only a few times. After intensive search on internet, I decided to use a hole saw and power drill to notch the galvanized pipes. It cost me $30+ to buy a good bi-metal hole saw, which did an amazing job. Don’t use those hole saw for wood as they tends to wear out easily on metal.

To notch my 2-3/8″ dia. galvanized pipe, I used the hole saw of the same size, which produces a very tight fit. I did find some comments about using slightly bigger hole saw (e.g. 2-1/2″ dia.) to leave a little bit tolerance. I tried that too and it worked just fine. But I still prefer using the same-dimension hole saw as the pipe

Other tips & Comments about notching steel tubes with hole saw:

- Pilot drill is a must option. Without it, your hole saw couldn’t stay on the circular tube to start cutting.

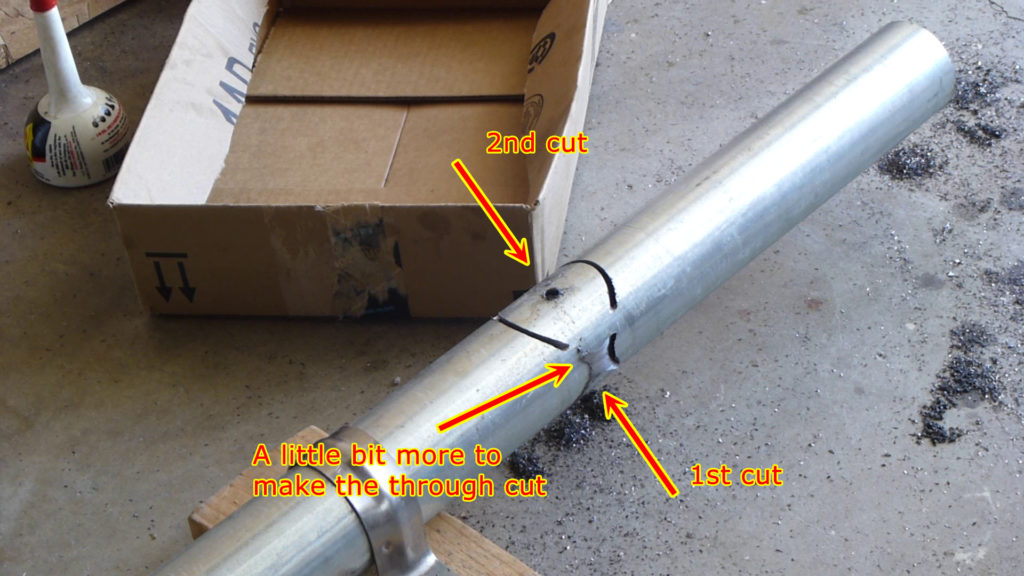

- The depth of the hole saw (the one I was using is about 1-1/2″ deep) is usually not enough to notch the tube (2-3/8″ in diameter) in one cut. You will need to flip the tube to start from the other side. Again, the pre-drilled pilot through hole will help line-up the two cuts.

- This cheap notching solution works best for T-shaped conjunction, in which you will only need to notch perpendicularly (90-degree) to the tube. I haven’t tried to notch with hole saw other than 90-degree, it might work, I guess, if you have a long pilot drill bit. Instead, I used miter saw to cut the galvanized pipe at an angle of 22.5 degree for diagonal (45 degree) conjunction. As you can see from the photo below, the fitting looks pretty loose, not as nice as the hole saw. But welding will help to fill the gap.

- Be patient and careful. Hole-sawing a steel tube is a slow process, and it generate a lot of heat! Applying a little bit lubricate onto the saw blades is always a good practice to help preserve the saw blade. Stop from time to time to give some break to the saw, power drill and, most importantly, yourself.

Related posts:

Leave a Reply