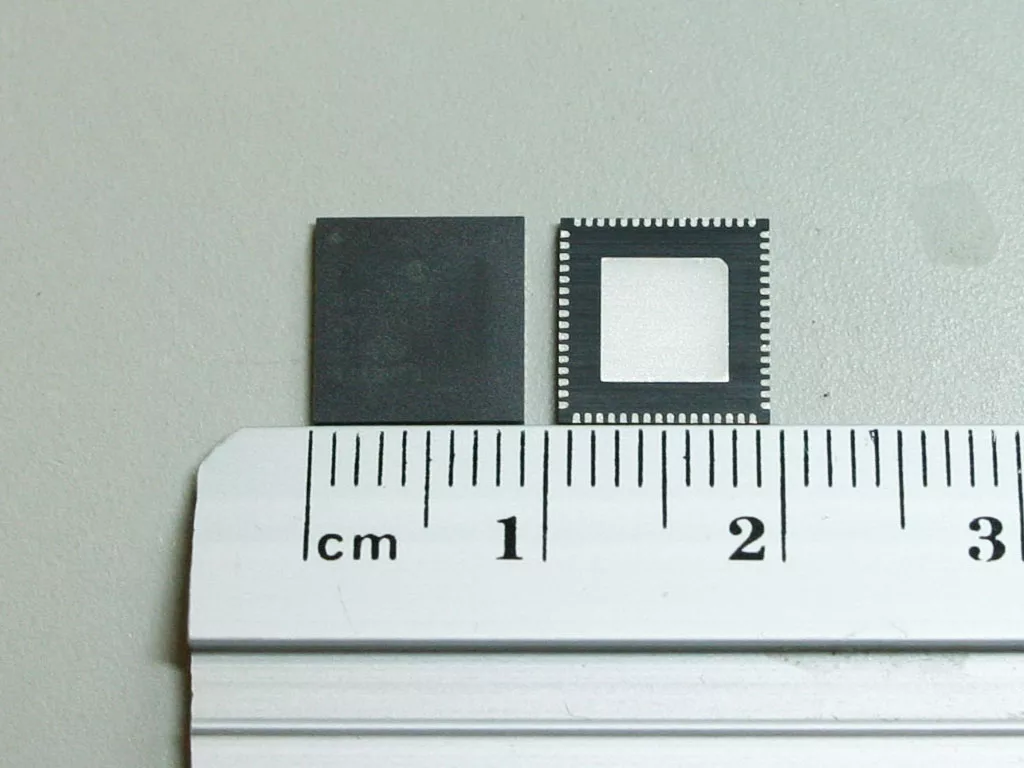

QFN pitch could be as small as 0.5mm. To make the things worse, there are no leads coming out of the package. The only externally accessible contacts are on the sides, which seem to be the last hope to solder by hand.

But impossible is nothing! I’ll show you with photos and video how I am able to manually solder a 64-pin QFN chip.

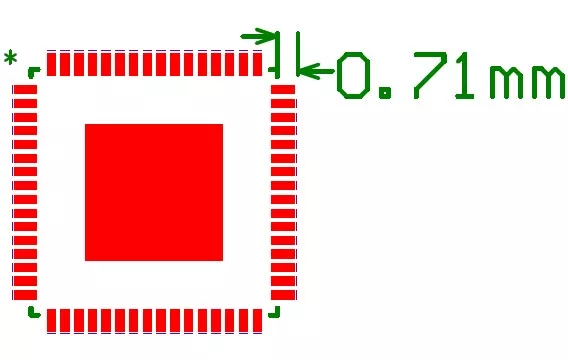

PCB footprint design tips

Design the pads slightly bigger than standard as you might need some extra room for the soldering iron to access. I extended the pads about 0.71mm out of the package and it is enough for the soldering tip to access.

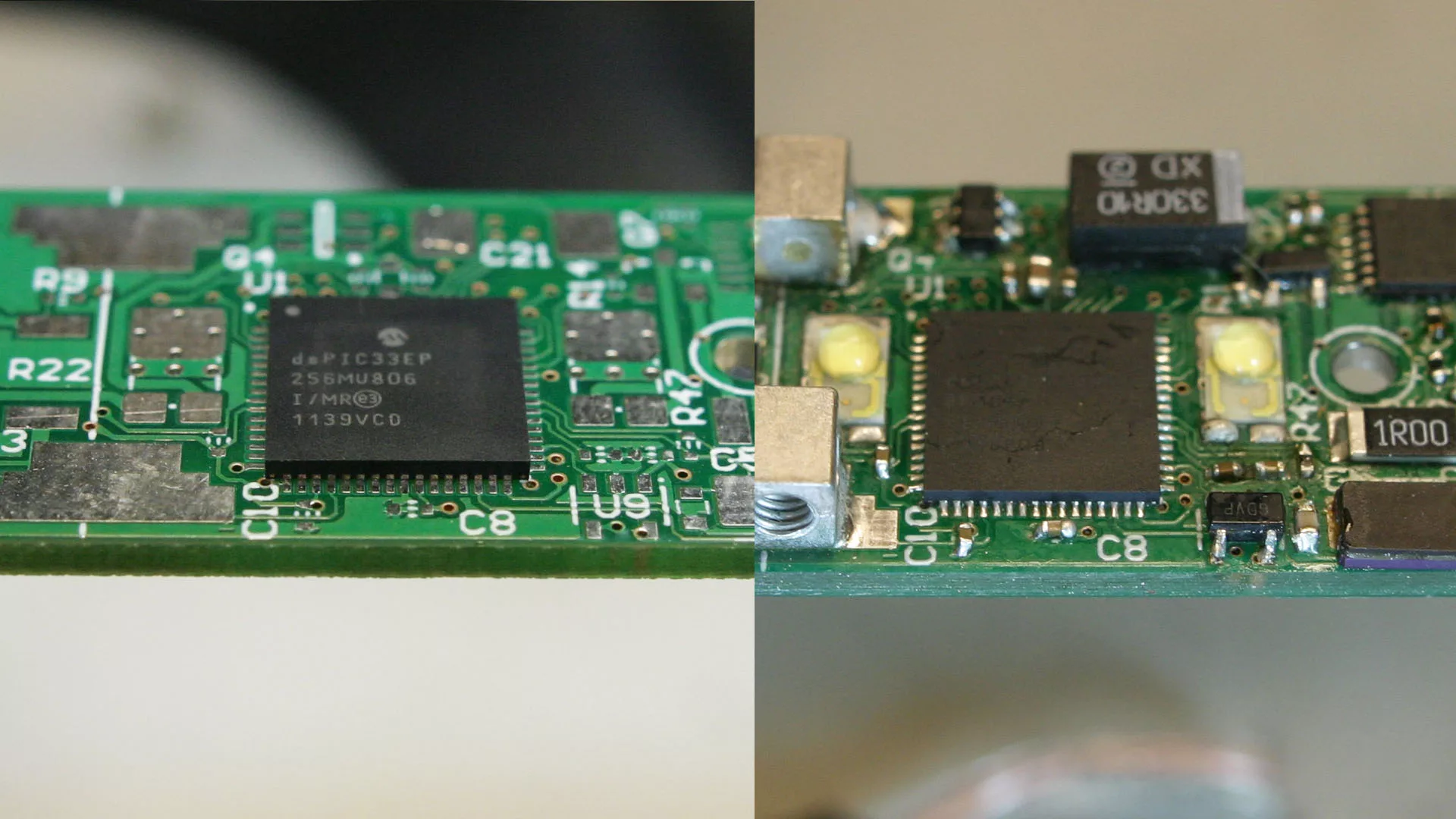

Principles behind QFN soldering

Bear in mind that, when dealing with small packages like QFN, you are not going to solder pin by pin simply because it is not quite doable. The way it works is to make use of the flux and let the molten solder naturally flow onto the chip leads and PCB pads. Solder’s surface tension will automatically separate itself from building bridges between pins. In some cases, however, too much solder is applied to so the bridge occurs, simply use a clean soldering tip or copper wick to remove the extra solder.

Leave a Reply